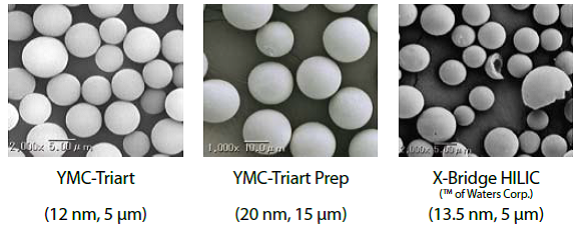

YMC-Triart

YMC-Triart and YMC-Triart Prep are bulk packing materials based on novel organic/inorganic hybrid silica particles. It is a pH stable and mechanically robust preparative grade HPLC stationary phase. This hybrid material can be produced in lot sizes of up to several hundred kg. It is well suited for production scale applications, as it is available up to multi-ton scale and suitable for repeated packing.

Their excellent durability allows effective cleaning of the gel with alkaline solution. These materials provide excellent mechanical stability, and can be packed into a column repeatedly.

Versatile hybrid-based material

Excellent mechanical stability

Easy scale-up from analytical to preparative

Excellent chemical durability

Regeneration with alkaline solution

| Product | Particle size (µm) | Pore size (Å) | Carbon content (%) | Usable pH range |

|---|---|---|---|---|

| Triart SIL | 3, 5 | 120 | - | - |

| Triart C18 | 20 | 1.0-12.0 | ||

| Triart C8 | 17 | |||

| Triart Prep C18-S | 10, 15, 20 | 120 | 20 | 2.0-10.0 |

| Triart Prep C8-S | 200 | 13 | ||

| Triart Prep SIL | 120, 200 | - | - |

YMC-Triart Prep is produced using micro-reactor technology in the bead formation process. This results in spherical particles with a highly uniform particle and pore size distribution which contributes to a reduction of the backpressure and to more reproducibility in surface modification.

Shearing and crushing of silica particles during repacking of columns leads to the formation of fines which results in increased backpressures. By using mechanically stable, spherical particles the formation of fines can be reduced.

Here, the high mechanical stability of YMC-Triart Prep is demonstrated by means of repeated packing and unpacking of a DAC column. Even after more than 10 repacking cycles for the same material the pressure does not increase. The absence of fines is shown by the constant backpressure. This makes YMC-Triart Prep a valuable phase for method development and especially for process optimisation!

In a production process, repeated injections of a solution of insulin in human plasma/serum are carried out. Consequently, absorption of protein and other impurities to the surface of the packing material reduces the retention capacity of the column.

Methodology:At this point a wash step with an alkaline solution (e.g. 0.1 M NaOH) removed the impurities and restores the full capacity of the column.

Problem:Silica materials are unsuitable for alkaline wash conditions, because of their poor stability at high pH.

Solution:Hybrid silica based YMC-Triart Prep has an excellent stability at high pH. It is stable to alkaline wash conditions which enables longer column lifetime.

This in turn reduces production costs: Lower consumption of packing material and less downtime due to column repacking. An extension of column lifetime by a factor of > two has been achieved!

The efficiency of a preparative purification depends on the selectivity of the stationary phase and its ability to separate possible impurities from the main product. An increase in selectivity would not only improve the degree of separation of the peaks, but also reduce the cleaning costs by increasing the load on the column. Furthermore, the amount of sorbent and consumption of mobile phase could be reduced to increase the yield for a given capacity or to improve the product quality.

With YMC-Triart the output could be increased at the same time as reducing costs.

Considering the overall costs, the proposed costs to obtain 1 kg insulin (purity ≥ 98.5%, starting from an initial purity 96.5%) with YMC-Triart Prep C8-L and appropriate solvents are 19% lower than with Daisogel SP-120-10-C8-BIO. In terms of process economy YMC Triart Prep C8-L scores the lowest overall purification costs and lowest absolute costs of the stationary phase. The amount of sorbent costs represents only about 1.7% of the overall costs, which is also the lowest percentage of all phases used.

Challenging Task

The use of 100% water as an eluent has been a challenge in HPLC separation for decades. Even today, many C18 materials suffer from unacceptable short lifetimes, as a result of the C18 chains collapsing which drastically reduces the separation performance. As a pioneer in the field of aqueous compatible phases, YMC has offered suitable products since the 1980’s for stable separations under aqueous conditions.

Solution

The ability to work with 100% aqueous conditions opens the door to extend the purification range to include polar compounds efficiently and economically. Due to their equivalent selectivity properties, processes can be easily scaled up from analytical to preparative scale.

In addition, desalting can be performed using a RP-C18 phase to reduce one step within the downstream processing. YMC-Triart Prep combines high mechanical strength with chemical stability to ensure robust, long-lasting and economic purifications.

/Triart%20App%20Purification%20of%20Polar%20Compounds.JPG)

Purification is the most critical step in the manufacturing process of peptide therapeutics. The right choice of chromatography media is crucial for cost-effective production. With its wide pH range (pH 2-10), YMC-Triart Prep C18-S provides you with full flexibility in the method development of peptide purification. Simple scale-up procedures ensure the reproducible result at manufacture-scale. A method for the purification of liraglutide with high resolution (antidiabetic peptide therapeutic, marketed by Novo Nordisk as Victoza®.) was successfully developed with YMC-Triart Prep C18-S under alkaline condition. The purity obtained for the target compound was 99.5%.

/Triart%20App%20Purification%20of%20Pedptides%20with%20Full%20Flexibiltiy.JPG)

| Title | Document Type | Language | Phase Type | Download |

| Purification of Peptides with Full Flexibility | Application Note | E | Download | |

| Purification of polar compounds with YMC-Triart Prep C18-S | Application Note | E | Download | |

| YMC-Triart Prep | Brochure | E | Download | |

| YMC-Triart Prep C18-S/C8-S Care and Use | Care and Use Instructions | E | Download | |

| MSDS YMC-Triart Bulk | MSDS | E | Download | |

| Bulk Packing Material for Preparative Chromatography | Overview | E | Download |